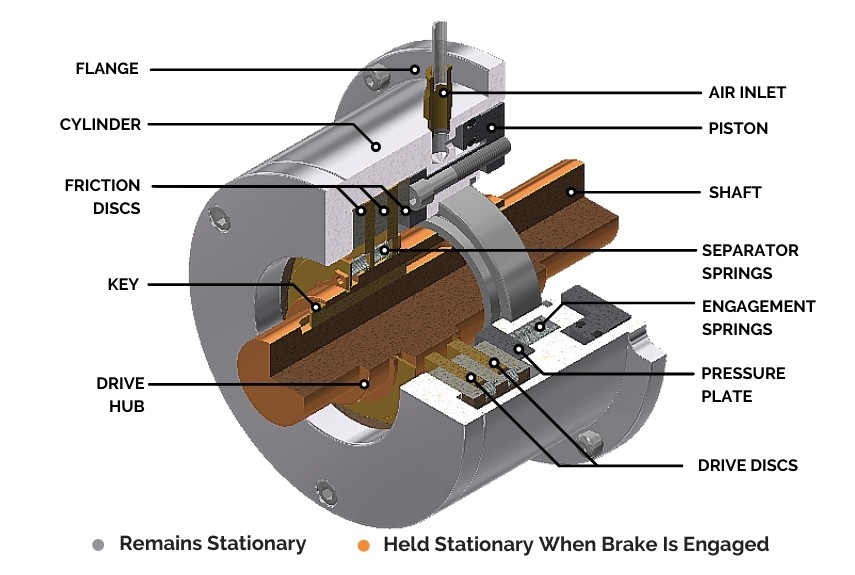

How It Works: Spring Engaged Friction Brake

Mach III spring applied brakes remain energized in the absence of air pressure. They are sometimes referred to as power-off brakes and are best suited for applications in which they are used to prevent the rotary motion of a load (holding).

BASIC CONNECTION

- The DRIVE HUB slides over the SHAFT. The drive hub includes a keyway which corresponds to the keyseat in the SHAFT. When a KEY is in place, the two members are connected.

- FLANGE mounted brakes such as the one shown must be connected to an anti-rotation restraint such as a machine frame or bracket with cap screws or shoulder bolts. A precision machined bolt pattern in the FLANGE is provided for this purpose.

- Lugs (tabs) on the outside diameter of the FRICTION DISCS fit into corresponding slots in the CYLINDER. The inside diameter of the DRIVE DISCS are connected to the DRIVE HUB via gear teeth or other drive geometries.

- The brake is capable of rotation in both clockwise and counterclockwise directions.

ENERGIZING THE BRAKE

- ENGAGEMENT SPRINGS located in the CYLINDER apply a constant, fixed amount of force to the PRESSURE PLATE which, in turn, applies force to the FRICTION DISCS and DRIVE DISCS.

- The SEPARATOR SPRINGS located between the FRICTION DISCS and DRIVE DISCS compress from the force, allowing full contact between the faces of the discs.

- The amount of torque transmitted is fixed by the force applied by the ENGAGEMENT SPRINGS.

- The FRICTION DISCS and DRIVE DISCS remain in contact and stationary until compressed air is supplied.

DISENGAGING THE BRAKE

- Compressed air supplied to the brake through the AIR INLET moves the PISTON assembly backward which compresses the ENGAGEMENT SPRINGS.

- As the ENGAGEMENT SPRINGS collapse, force is removed from the PRESSURE PLATE allowing the SEPARATOR SPRINGS to push the FRICTION DISCS and DRIVE DISCS apart.

- Once adequate air pressure is present to fully separate the discs, the DRIVE DISCS and SHAFT are free to rotate.

- Timing for full disengagement is short but depending upon the cycle rate of the application, it is sometimes advisable to install a quick exhaust port to allow the air to exit the brake more quickly.