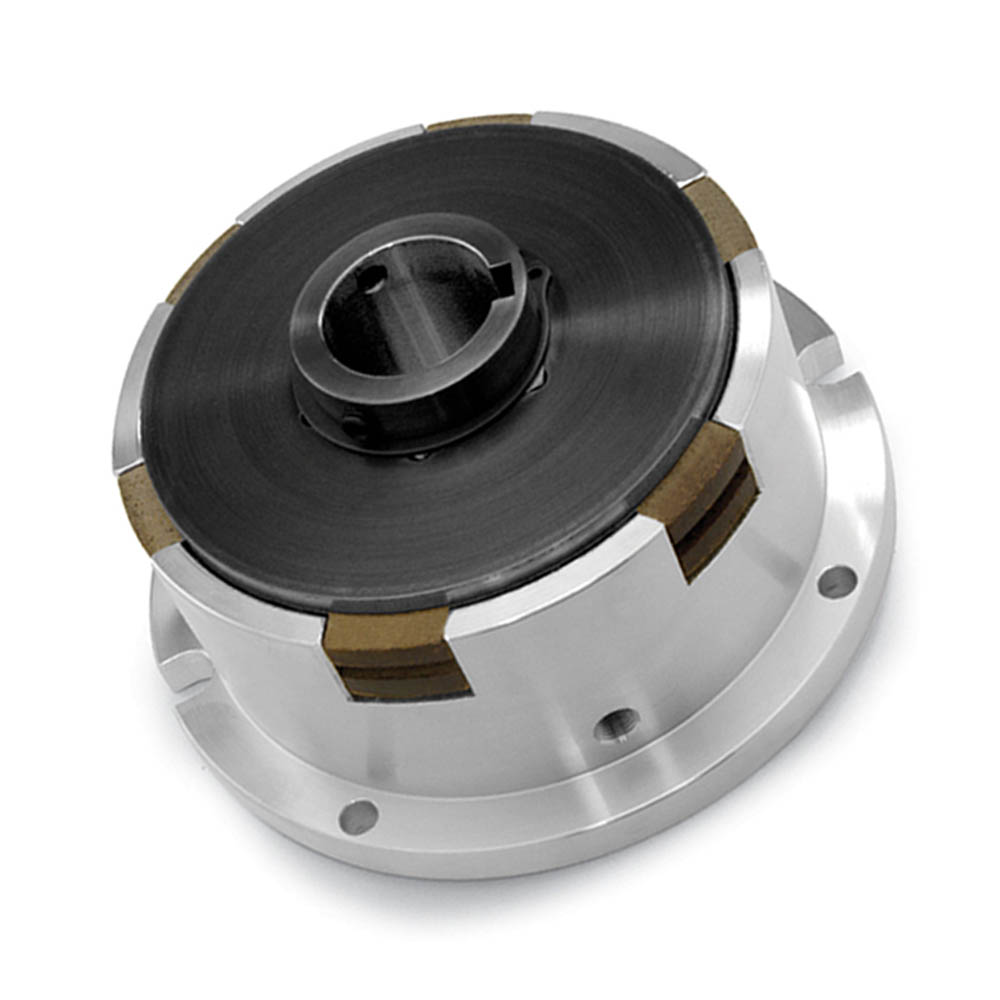

Air Engaged Brakes

Flange Mounted Friction Brakes for Power Off Holding

Function: Holding, Failsafe (Non-Cycling Applications)

Drive Arrangement: Machine Frame or Bracket to Shaft

Operation

- Air pressure compresses drive and friction discs to produce torque.

- Torque is linear in response to the air pressure applied.

- Release springs provide positive disengagement when air is exhausted.

Mounting

- The brake flange bolts to a machine frame or other fixture, the shaft inserts into the bore and is fixed with a customer supplied key.

- Can also be mounted mid-shaft with the flange connected to a bracket.

- Air engaged friction brakes are designed for horizontal mounting. If vertical mounting is required, consult engineering.

Applications

- Air engaged friction brakes are suitable for stopping, holding and cycling applications.

- Maximum RPM varies by model and is listed on the PDF detail sheet (see table below). Consult engineering if the intended application exceeds the listed maximum RPM.

Design Features

- Air engaged brakes are made-to-order with any bore size up to the maximum shown for easy installation.

- Drilled and slotted flange allows for variable installation arrangements.

- Low coefficient friction lining versions are available for applications requiring slip or a narrower torque range. Contact engineering for details.

Customization Options

All Mach III products can be customized to meet the needs of your application.

" />| Product Code | Torque @ 80 PSI | Maximum Bore with Standard Keyway | Detail Sheet | Request 3D CAD Model |

|---|---|---|---|---|

| B2F2R-STH | 100 lb-in | 0.500 in (12 mm) | View PDF | Request |

| B3F2R-STH | 267 lb-in | 1.000 in (24 mm) | View PDF | Request |

| B4F2R-STH | 760 lb-in | 1.250 in (31 mm) | View PDF | Request |

| B5F2R-STH | 1,584 lb-in | 1.438 in (38 mm) | View PDF | Request |

| B6F2G-STH | 3,118 lb-in | 2.000 in (52 mm) | View PDF | Request |

| B8F2K-STH | 4,788 lb-in | 2.375 in (66 mm) | View PDF | Request |

| BAF2K-STH | 9,673 lb-in | 2.750 in (72 mm) | View PDF | Request |