Prevent Heavy-duty Drill Overloads With Torque-limiting Couplings

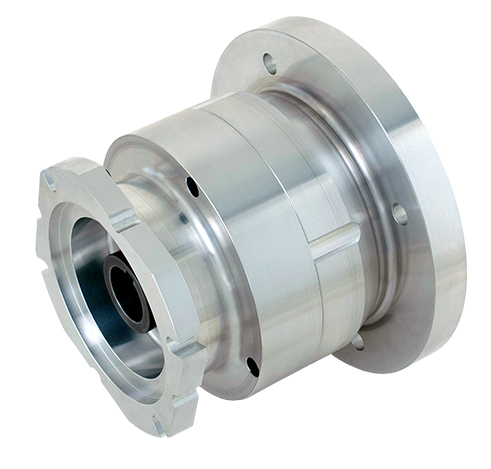

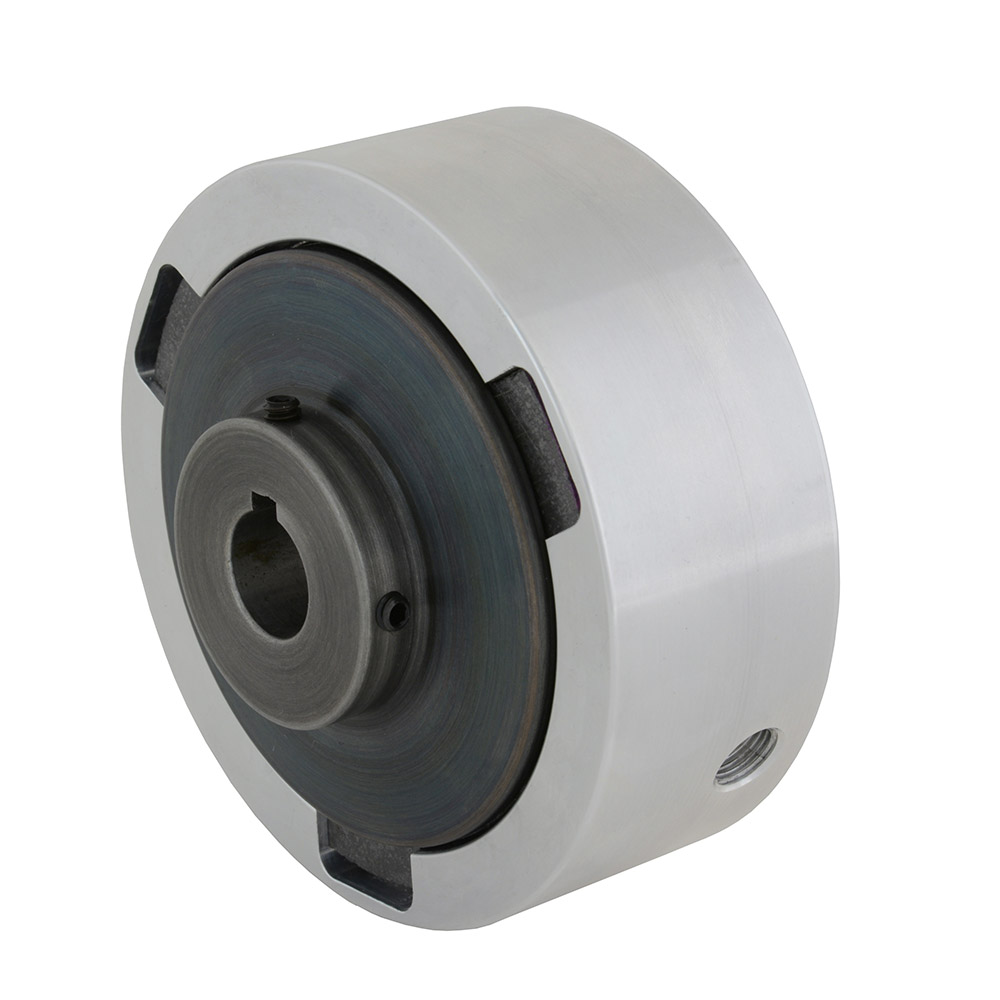

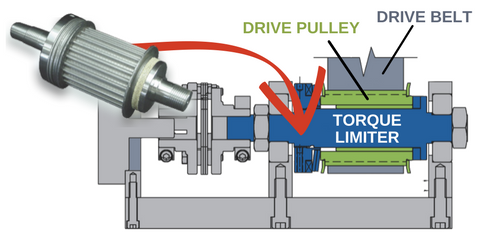

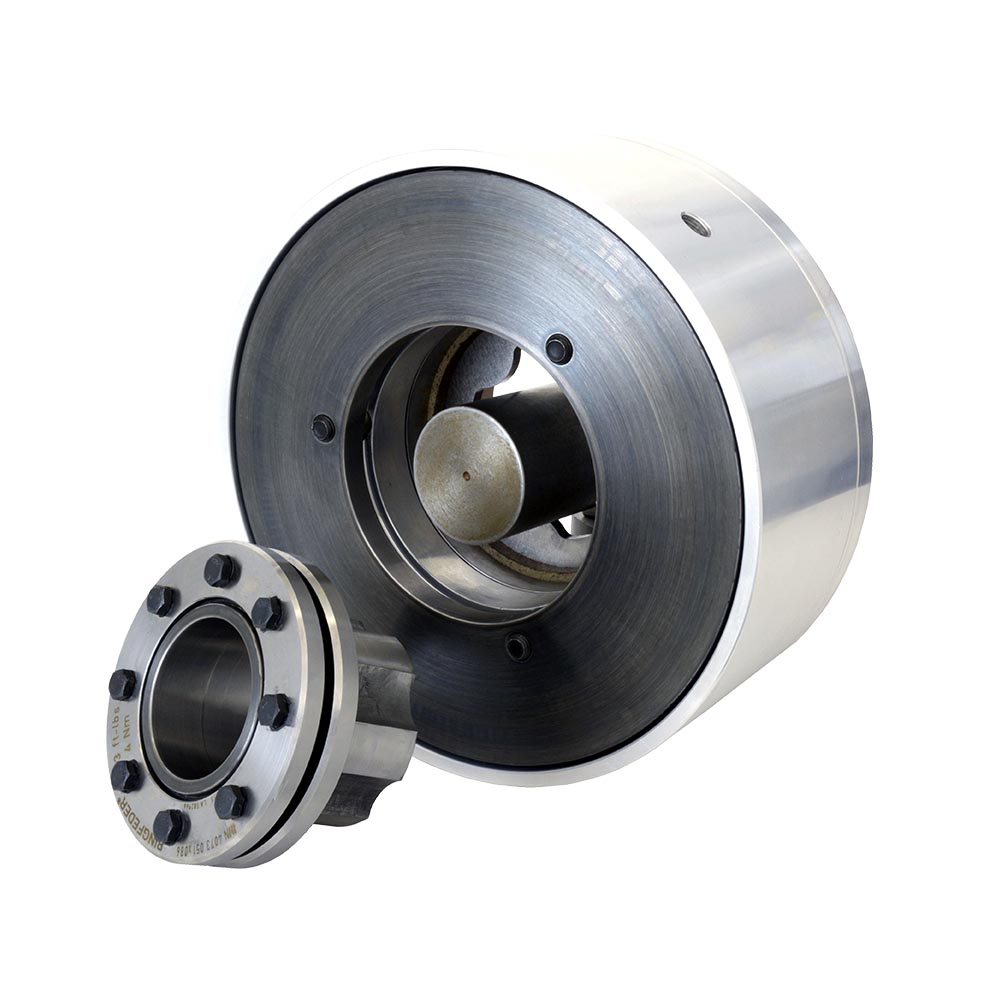

Ensuring equipment and operator safety is critical when using heavy-duty power drills to open and close gate valves, butterfly valves and other high-torque rotary actuators. To this end, the Mach III T4X2R-STH torque-limiting coupling minimizes the risk of machine damage by slipping when the torque exceeds a preset limit, preventing harmful overloads in power drill… Read more »

Read More